FUTUREBUILD® LVL hyPLANK®

Features & Benefits

- Individually proof tested for safety and performance

- Tough and long lasting, especially in corrosive environments

- Wax emulsion end seal reduces moisture ingress

- Lightweight and versatile

- Veneers are bonded together using type 'A' (marine) bond, known for long-term durability in structural applications

- Each piece is branded for ease of identification

- Stringent quality control – EWPAA certified

- Span Tables available for use in accordance with AS/NZS 1577 - refer brochures below

- Manufactured from sustainably-grown NZ plantation pine

- Available Forest Stewardship Council® (FSC®) certified (FSC® C007103) upon request

* Contact Futurebuild® LVL for further information.

Compliance

hyPLANK is manufactured in accordance with AS/NZS 4357, Structural laminated veneer lumber and is designed to be used as a non-modular scaffold plank as a part of a working platform in accordance with the requirements of AS/NZS 1576.1 and AS/NZS 1577.

Futurebuild LVL is committed to manufacturing innovative engineered building products. For quality assurance the Futurebuild range is manufactured with independent audit processes and product certification.

All hyPLANK is manufactured using a Type ‘A’ (marine) bond with less than 0.5mg/L formaldehyde emissions from the final product (equivalent to E0).

hyPLANK at the time of dispatch from the manufacturing site has a moisture content of between 8-15%.

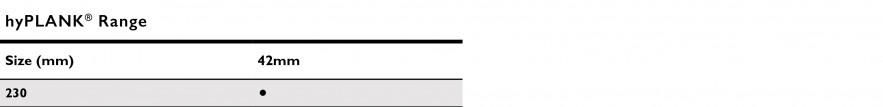

Range

- hyPLANK is manufactured in a 230x42mm section, available off the shelf in 3.0, 3.6, and 4.2m lengths

Software

Photo Gallery

Brochure

Futurebuild LVL Residential Design Guide NZ

Manufactured by Futurebuild LVL, Laminated Veneer Lumber (LVL) is the engineered solution for residential housing design and

construction.

Futurebuild LVL Specific Engineering Design Guide

Properties and structural characteristics for the Futurebuild LVL range for use by specifiers and engineers for specific design LVL projects.

hyPLANK is a strong, lightweight Laminated Veneer Lumber (LVL) scaffolding plank. The structural uniformity of LVL, combined with the strict quality control processes during manufacture, ensures hyPLANK is safe and fit for purpose as scaffold planking.

Technical Note

Futurebuild LVL and Treatment For Use in Buildings

Technical Note relating to treatment for use in buildings

Futurebuild LVL Trouble with Substitutes

Think hard and check before substituting one building product for another. Get it wrong and you could be creating quality issues and have trouble getting a Code Compliance Certificate.

Information Bulletin

Futurebuild LVL computeIT Software for Engineers Flyer

computeIT® is designed to aid in the specification of heavy Laminated Veneer Lumber (LVL) structural

members and non-residential structural systems. Learn more in this flyer on the computeIT software suite.

Cad

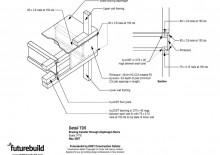

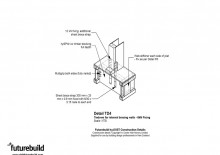

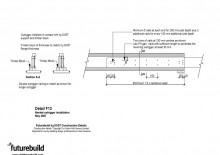

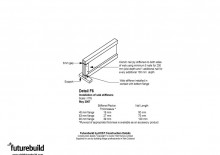

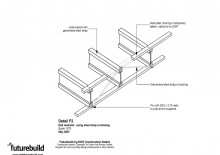

HYJ025 (TD3)

Tie-down for external bracing wall- 6 and 12 kN fixing details - bracing wall perpendicular to joist (Detail TD3)

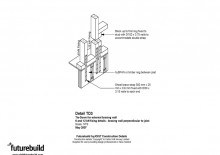

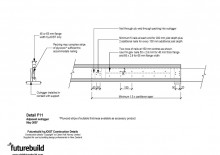

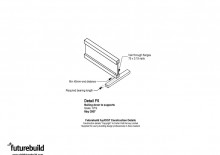

HYJ024 (TD2)

Tie-down for external bracing wall -6 and 12 kN fixing details - bracing wall parallel to joist (Detail TD2)

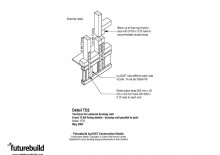

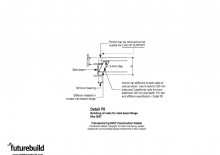

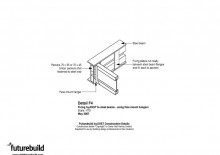

HYJ023 (TD1)

Tie-down for external bracing wall using rimboard using 6 12kN fixing detail (Detail TD1)

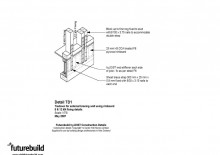

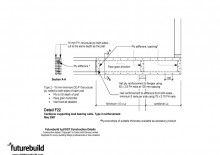

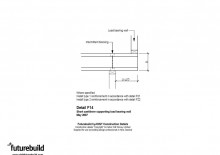

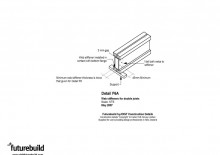

HYJ022 (F22)

Cantilever supporting load-bearing walls- Type 2 reinforcement (Detail F22)

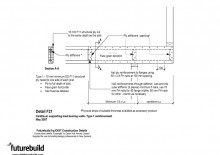

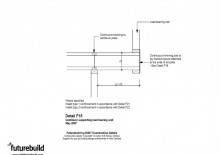

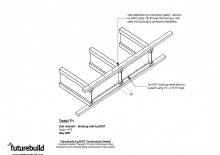

HYJ021 (F21)

Cantilever supporting load-bearing walls- Type 1 reinforcement (Detail F21)

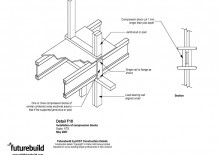

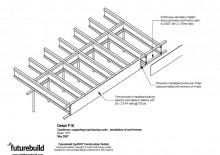

HYJ018 (F16)

Cantilevers supporting load-bearing walls - installation of end trimmer (Detail F16)

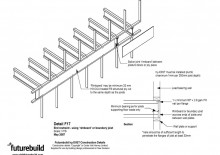

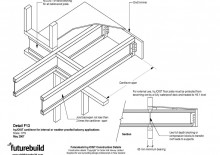

HYJ015 (F13)

hyJOIST cantilever for internal or weather-proofed balcony applications (Detail 13)

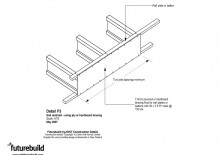

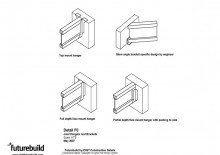

HYJ005 (F4)

Fixing hyJOIST to steel beams - using face mount hangers (Detail F4)

Case Studies

Building Product Information

Building Product Information Sheet and Product Technical Statement for Futurebuild hyPLANK scaffold planks

Sds

Futurebuild LVL SDS Untreated LVL and hyJOIST

Safety Data Sheet glued product used in residential, commercial, and industrial construction, and/or general purpose building material.